If you’ve ever picked up a box, you’ve probably seen the circular graphic on its underside. At first glance, all those words and numbers look like they form another language, don’t they? This graphic’s known as a box maker’s certificate (also called a BMC). It’s a smart, simple design that tells you a lot of what you need to know about a corrugated box and its construction.

What’s a Box Maker’s Certificate?

It’s a seal printed on the bottom of a box that tells you how strong it is. It’s not legally required, but it’s proof that the box has been properly tested and rated.

How do I read a Box Maker’s Certificate?

There’s a lot of info listed on a BMC and it can be a little overwhelming at first. But, once you know how to read it, you’ll be able to quickly know the strengths and properties of the box in your hands.

There are two versions of a BMC, let’s explore both now.

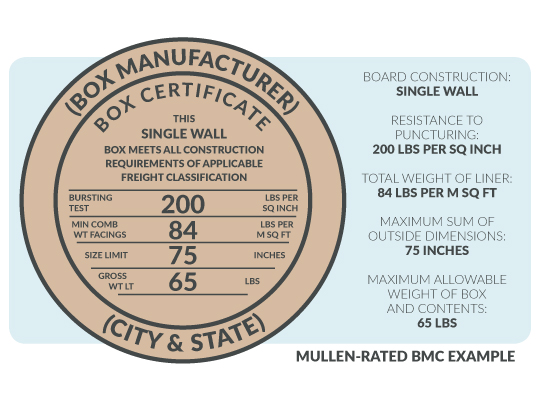

Mullen-Rated Box Maker’s Certificate

Mullen Test measures the wall strength of a box. This determines how much pressure it takes to puncture or rupture a box wall (hence its other name, the burst test). This is especially worthwhile to know if loose or oddly-shaped objects will be shipped in a Mullen-rated box.

Here’s what each area of a Mullen-rated BMC means:

Box Manufacturer is the company who made the box you’re holding. It’s always listed at the top of the outer ring.

Board Construction is the thickness and strength of the box sides—listed as either single wall, double wall or triple wall. Visit our Corrugate page to learn box about box walls.

Bursting Test is the box’s resistance to having its walls punctured. The most common Mullen-rated box comes in at a resistance of 200 pounds per square inch.

Minimum Combined Weight Facings is the total weight of the manufactured liner before it’s cut down into boxes. In the above example, the total weight of the non-cut liner would be 84 pounds per thousand (M) square feet.

Size Limit is the total sum of the outside dimensions of the box. This is useful to know for storage and shipping purposes (like planning pallet loads or calculating dim weight). Visit our Corrugate page to learn more about inside and outside dimensions.

Gross Weight Limit is the maximum allowable weight of the box and its contents. Boxes loaded above the listed weight tend to get damaged very easily due to its integrity being compromised.

City & State is where the box was made and shipped from. It’s always listed at the bottom of the outer ring.

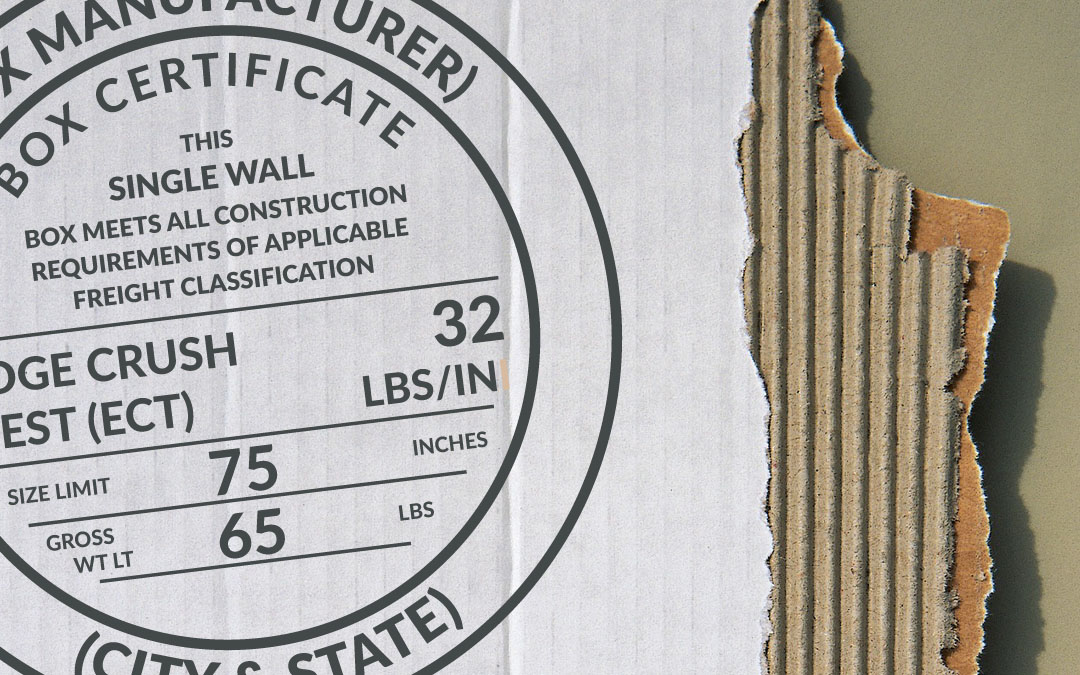

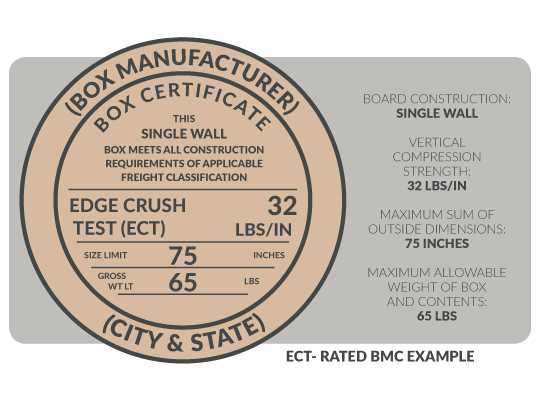

ECT-Rated Box Maker’s Certificate

Edge Crush Test (ECT) measures the stacking strength of a box. This determines how much pressure it can handle before being crushed. Since most shipping is done by stacking boxes on skids now, this is the ideal strength test for shipping individually-boxed products and merchandise.

Here’s what each area of an ECT-rated BMC means:

Box Manufacturer is the company who made the box you’re holding. It’s always listed at the top of the outer ring.

Board Construction is the thickness and strength of the box sides—listed as either single wall, double wall or triple wall. Visit our Corrugate page to learn box about box walls.

Edge Crush Test (ECT) is the vertical compression strength of the box walls. The most common ECT-rated box comes in at a strength of 32 pounds per inch, listed as 32 ECT.

Size Limit is the total sum of the outside dimensions of the box. This is useful to know for storage and shipping purposes (like planning pallet loads or calculating dim weight). Visit our Corrugate page to learn more about inside and outside dimensions.

Gross Weight Limit is the maximum allowable weight of the box and its contents. Boxes loaded above the listed weight tend to get damaged very easily due to its integrity being compromised.

City & State is where the box was made and shipped from. It’s always listed at the bottom of the outer ring.

Both ECT and Mullen are valid methods for measuring the suitability and stability of a corrugated box. Now that you’re a veritable expert on how to read a box maker’s certificate, you’ll be able to make the right choice for your product’s shipping and storage needs.

Interested in packaging and all its components? Visit our Product Knowledge section to learn more.